CNC3018¶

La machine

¶

¶

Outils¶

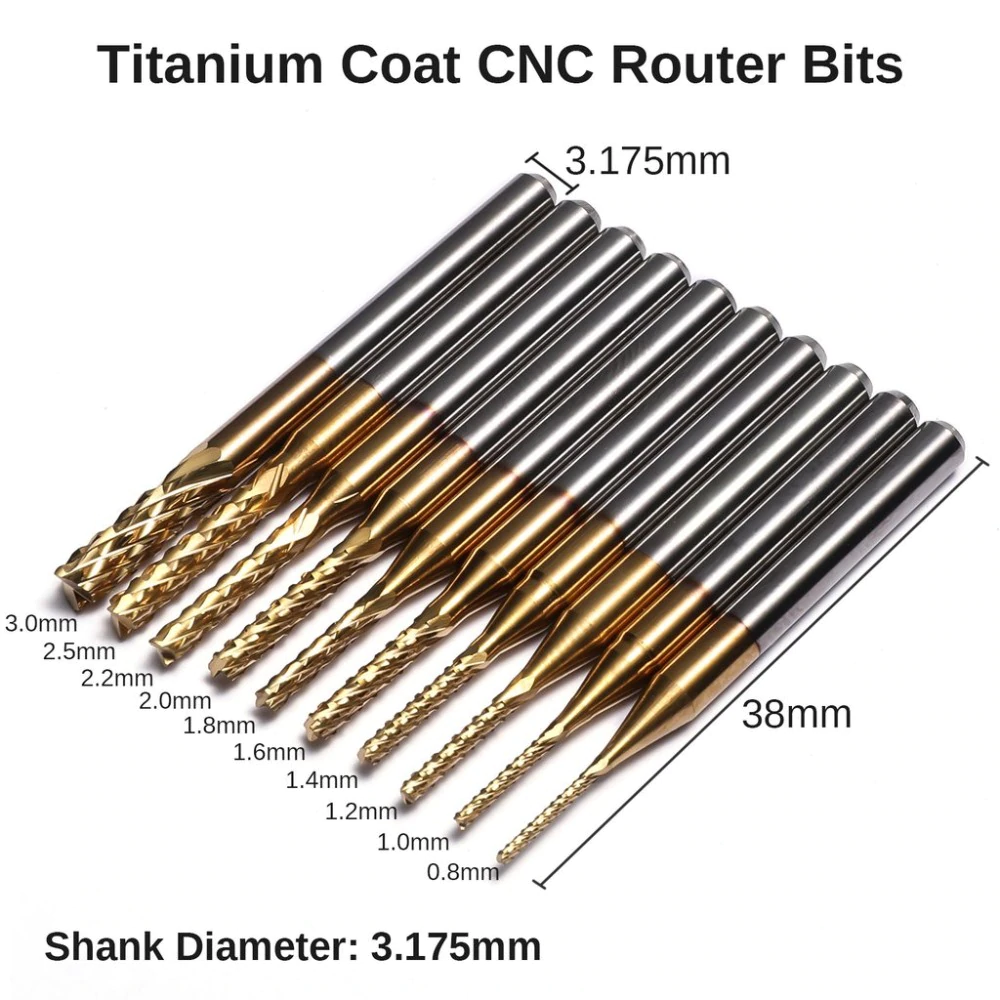

le porte outil est au format 3.175mm (1/8")

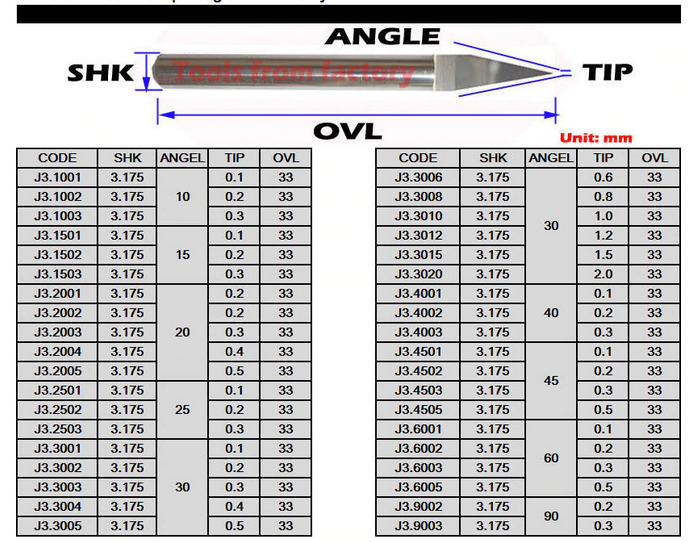

fraise en forme de V angle entre 10° et 90°

fraises de détourage de 0.8mm à 3.0mm

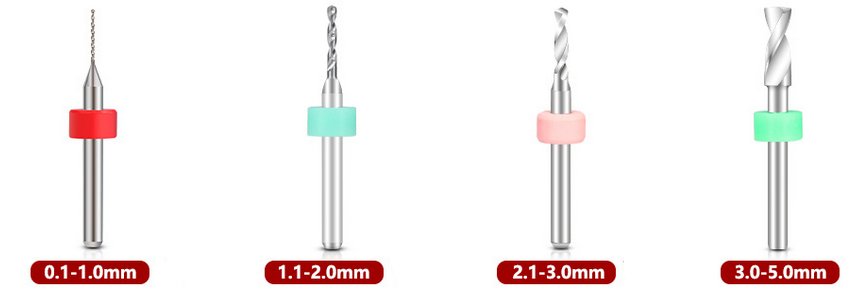

forets de perçage de 0.1mm à 5mm (pas de 0.1mm)

vitesse¶

| 10° V-Bit with 0.1mm tip | |

| Parameter | Value |

| tool vbit 10° | 0.1mm tip |

| cut Z | 0.1mm |

| effective tool width | 0.1175mm |

| feedrate | 200 |

| spindle speed | 20000 (8000*) |

| passes | 2 |

| pass overlap | 10% (0.10 in flatcam) |

| 30° V-Bit with 0.1mm tip | |

| Parameter | Value |

| tool vbit 30° | 0.1mm tip |

| milling depth | 0.1mm |

| effective tool width | 0.15359mm |

| feedrate | 200 |

| spindle speed | 20000 (8000*) |

| passes | 2 |

| pass overlap | 13% (0.13 in flatcam) |

(*) vitesse réelle de la CNC3018

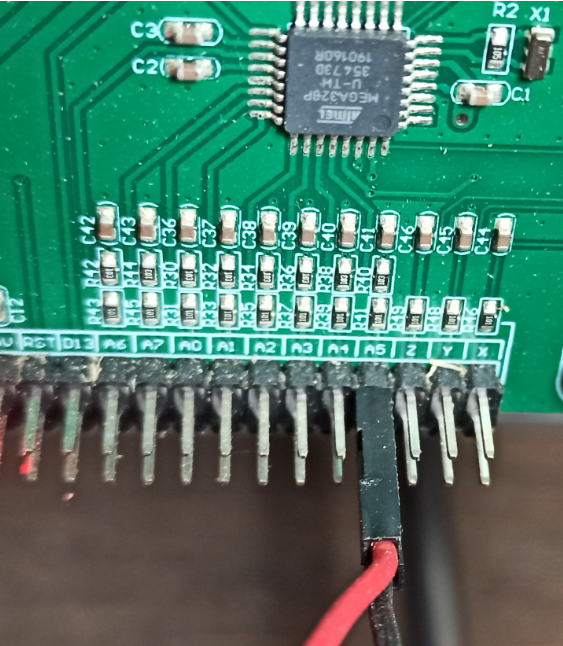

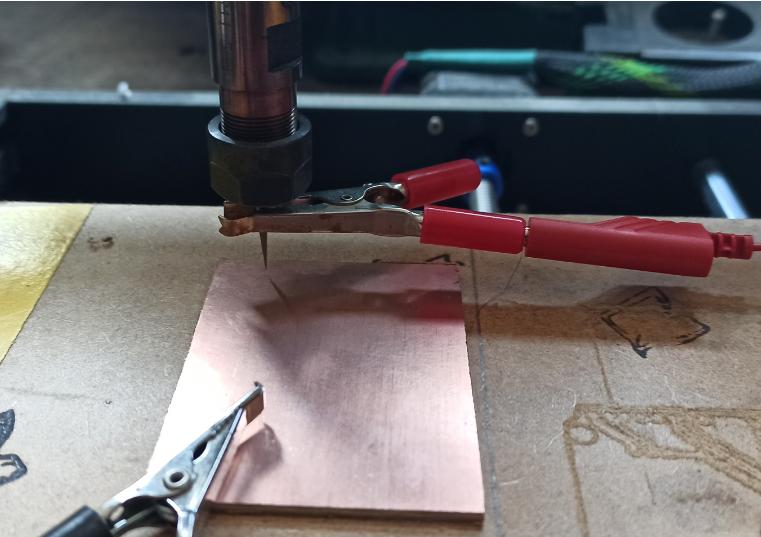

Palpeur axe Z¶

connexion du palpeur entre A5 et GND

Connecter la broche et a l'outil de gravure la l'entrée A5 de la carte contrôleur GRBL.

Connecter le PCB a la masse GND, si besoin utiliser du ruban cuivre, ou souder un fil.

Gravure¶

Perçage¶

GRBL¶

version 1.1f

config¶

$0=10

$1=25

$2=0

$3=5

$4=0

$5=0

$6=0

$10=1

$11=0.010

$12=0.002

$13=0

$20=0

$21=0

$22=0

$23=0

$24=25.000

$25=500.000

$26=250

$27=1.000

$30=1000

$31=0

$32=0

$100=1600.000

$101=1600.000

$102=1600.000

$110=1000.000

$111=1000.000

$112=800.000

$120=30.000

$121=30.000

$122=30.000

$130=200.000

$131=200.000

$132=200.000

en 1/32 pas avec HW , soft limit et homing

$0=10

$1=25

$2=0

$3=0

$4=0

$5=0

$6=0

$10=1

$11=0.020

$12=0.002

$13=0

$20=1

$21=1

$22=1

$23=0

$24=100.000

$25=500.000

$26=250

$27=1.000

$30=1000

$31=550

$32=0

$100=800.000

$101=800.000

$102=800.000

$110=1000.000

$111=1000.000

$112=800.000

$120=50.000

$121=50.000

$122=50.000

$130=200.000

$131=200.000

$132=200.000

$140=100.000

$141=100.000

$142=100.000

$150=500.000

$151=500.000

$152=500.000

Updated by Frédéric Blanc over 3 years ago · 17 revisions